Thermal imaging

The importance of thermal imaging

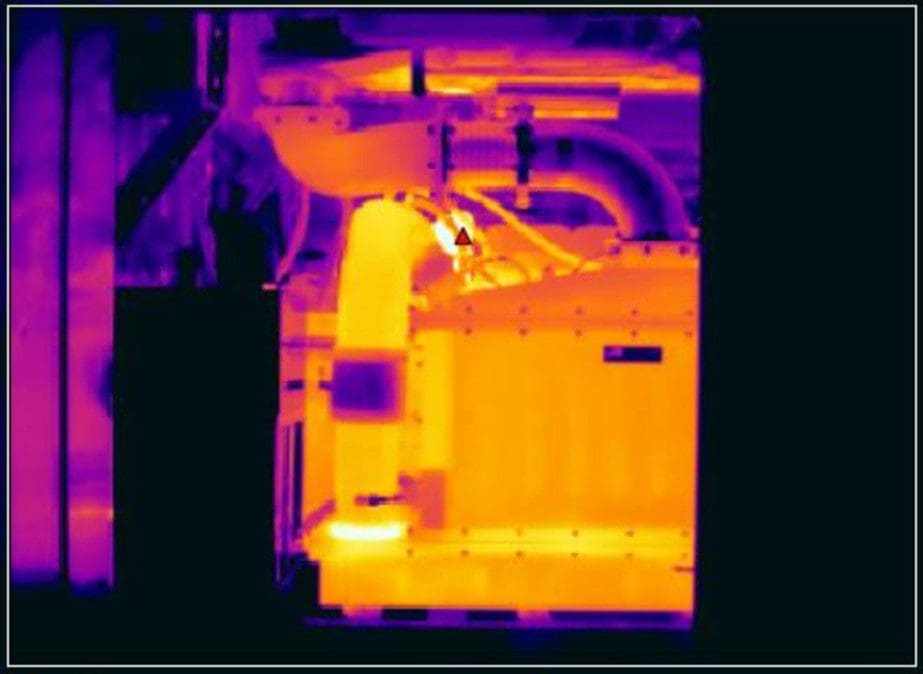

Diesel engines designed for operation in potentially hazardous areas have many thermal barriers applied to keep external surfaces below required temperature class (typically T3=200degC). Most common thermal barriers are:

- Jacket water cooling on exhaust system

- Thermal isolation compounds on induction system

It is important to be aware that both methods do not guarantee lifetime protection against hot surfaces.

Blocked venting lines may lead to air pockets inside the cooling channels. Thermal isolation compound may be subject to aging and lose its properties over time. In both cases thermal barriers will no longer be effective. Therefore, we recommend periodical performance check for all thermal barriers installed on diesel engine and there is no better method to do so than thermographic imaging.

New release of NORSOK Z-015 standard (Z-015:2020) requires also thermal imaging for diesel engines not approved for operation in Zone 2. In this case thermal image shall be taken under the most extreme operational conditions and (here is the most important part) define time needed to cool down all surfaces below 200°C after diesel engine shutdown from this operational condition.

Diesel engines not approved for operation in hazardous areas may have effective ignition sources during normal operation, but also after in the period following shutdown. This is the main reason those engines must be placed at an adequate distance from hazardous areas. Taking thermographic measurement after diesel engine shutdown allows to define remaining ignition sources and time needed to bring engine back to safe state. This is valuable information for personnel responsible for equipment location.

JB Safe Diesel offers thermographic imaging using calibrated infrared camera. Our service covers on site measurement and final report that shows thermographic signature of the diesel engine.